Air Nipper

Air Nipper Manufacturers, Suppliers and Exporters in India

Contek is one of the most experienced and reliable manufacturers, suppliers, and exporters of high-performance Air Nippers in India, Get Compact, Lightweight Design and High Cutting Precision Air nipper at latest prices as customer requirements. We have extensive experience of understanding the needs of industrial automation and precision cutting needs, we provide solutions with the latest technology and robust engineering. We keep our air nipping machines updated on a regular basis to match future-generation manufacturing process needs and cater to industries that need more precision, speed, and efficiency.

Industrial Square Air Nipper Manufacturers in India

A well-known Air Nipper manufacturers in India, We are providing the best quality of Air Nippers such as:

Pneumatic Air Nipper:

We offer Pneumatic Air Nippers that are designed to be used with compressed air at high speed for fine cuts. These are best suited for repeat and repetitive operations where there is no room to settle for anything. They are perfectly suited for semi-automatic applications and deliver silky output even after long hours of usage.

| Specification | Details |

|---|---|

| Operating Pressure | 0.4–0.6 MPa |

| Cutting Capacity | Up to 8 mm (Plastic/Wire) |

| Cycle Time | < 1 second per cut |

| Mounting Style | Fixed / Handheld |

| Ideal Use | Semi-automatic, repetitive operations |

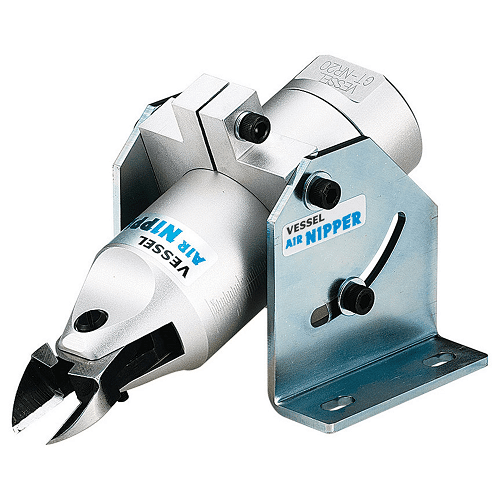

Vessel Air Nippers:

Our Air Nippers are Vessel-compatible and designed to be employed with the best Vessel blades which make entirely clean and burr-free cuts. They're especially invaluable when employed on electronics manufacturing, wire trimming, and other applications where utmost precision and sensitivity are paramount. We assure every single one of them to worldwide standards of quality and performance.

| Specification | Details |

|---|---|

| Compatibility | Vessel Blade Standard |

| Precision Tolerance | ±0.01 mm |

| Applications | Wire Trimming, PCB Lead Cutting |

| Blade Type | Interchangeable (Flat, Angled, Radius) |

| Surface Finish Quality | Burr-free, smooth finish |

Sliding Air Nipper Bracket Models:

We manufacture Air Nippers with sliding bracket mounts to allow for movement or dynamic operations flexibility. The air nippers can move along production lines and clip parts as they move. They function best in high-speed conveyor systems and robots where fixed-angle cutting is not suitable.

| Specification | Details |

|---|---|

| Mount Type | Sliding Bracket |

| Travel Distance | 20–100 mm (adjustable) |

| Operating Speed | Up to 60 cuts/min |

| Applications | Conveyor Lines, Robotics Integration |

| Movement Control | Pneumatic Linear Actuation |

Inline Air Nippers are lightweight and compact:

We design and manufacture convenient inline air nippers for use in confined applications but never compromising on usability. The packages cut square, axial cuts without calling for complicated mounting and deflection. They find use in closely-spaced applications such as electrical assembly stations and mini jigs.

| Specification | Details |

|---|---|

| Orientation | Inline / Axial |

| Size | Compact: Ø20–30 mm body |

| Cutting Force | 50–100 N |

| Use Case | Electrical Assembly, Tight Spaces |

| Noise Level | < 65 dB |

Rotary Actuated Air Nippers:

Our rotary-actuated air nippers cut at any angle of approach through the rotating motion action. They are appropriate for robot arms in high-technology production cells. They offer variable positioning and smooth cutting when making angular or multi-planar cuts through by using best rotary technology.

| Specification | Details |

|---|---|

| Actuation Type | Rotary Pneumatic |

| Rotation Angle | 0–180° (Programmable) |

| Application Areas | Multi-axis Robots, Complex Cuts |

| Mounting Orientation | Any (360° Flexible) |

| Blade Material | High-Speed Steel (HSS), Coated Alloys |

Features of our Air Nippers

One of the leading Air Nippers suppliers in India, our all-types of Air Nippers are included with new technological formulations such as:

- High-Precision Blades: We use high-grade alloy steel blades heat-treated for hardness and longevity. They will slice through a range of material from soft metals, rubber, to plastic. Easy blade change design reduces manufacturing downtime.

- Advanced Pneumatics: We use effective pneumatic constructions made using low-friction cylinders to deliver more rapid actuation and reduced air usage. Not only does this improve performance, but it also keeps operating costs down in the long run. Each unit is chosen to deliver smooth, steady motion without lag or jerk.

- Modular Designs: Our air nippers are built with modularity to allow simple integration into automated lines, tailor-made fixturing, and robot arms. Sliding nippers and mounting configurations allow simple adjustment to different operating angles and positions. Modularity is also easy to maintain and replace.

- Noise and Vibration Reduction: We are matched with the new interior dampers for reduced noise and vibration in high-profile operation conditions. This ensures even higher comfort and safe operating surface area for operators in high-volume production factories. It also helps to support higher precision by automated systems through fewer movement deviations.

Advantages of choosing Air Nippers

Our all types of new Vacuum Air Nippers for Stamping Machines gives multiple types of benefits:

- Increased Production Efficiency: We create air nippers that provide humongous payback in cycle time and rate of production on the commerce factory floor. They prevent downtime and provide perfect work flow with quick actuation and frictionless cut action. This is worth enough in high-volume and time-critical operation in commerce.

- Lower Maintenance Costs: We ensure that our nippers are maintenance-friendly and have low-maintenance components that are easy to replace when necessary. The wear components also comply with standards and are easy to order to enhance ease of maintenance. This lowers your ownership cost and minimizes production downtime.

- Custom Fit to Automation: We ensure our air nippers' automation system is adaptable to fit equipment such as robot arms, pneumatic tubes, and conveyor lines. Our pneumatic air nippers models and sliding brackets are appropriate for modern industrial settings. It translates to streamlined upgrades to automation with reduced tool changes.

- Operator Safety & Ease of Use: Special attention towards safety and ergonomics is directed towards all our products. Light-weight, balanced, and low-recoil air nippers are produced by us, thus making them comfortable to carry when working for longer hours. Sound insulation and controlled release of air are implemented in every unit as a safety measure.

Applications of Air Nippers

Being the best Air Nippers exporters in India, our all types of Air Nippers are included with new feature and highly used in multiple applications such as:

- Electronics & PCB Production: We have vessel air nippers used to trim electronic component leads, terminal wire, and plastic insulators without compromising the integrity of the board. Our vessel air nippers can do such minute-level and sensitive work. They make clean cuts with precision without influencing the integrity of circuit boards.

- Automotive Component Assembly: We manufacture air nippers used extensively across car assembly lines for trimming plastic components, cable straps, and mold gates. They are specifically designed for robot assembly lines with high speed and conveyor lines because they are precise and fast. They enable production efficiently and reduce the possibility of rework.

- Plastic Injection Molding: We supply precision air nippers to cut off runners and sprues off injection-molded plastic parts. They are installed in high-volume molders and may be utilized in robot trimming stations. Our sliding air nipper bracket systems maximize their performance for synchronized trimming operations.

- Packaging Industry: We supply air nippers to facilitate cutting of films, edge trimming, and strap stripping in automatic packaging machines. The device facilitates high-speed production with symmetrical cutting on all the packs of units. It is designed compact space-saving with small dimensions to find small spaces in automatic lines.

- Compressed Air Systems Maintenance: We also provide spares for air compressors that are compatible with our pneumatic air nippers to facilitate easy handling. Spares provide uniform pressure and smooth air flow. Air system maintenance is hand in hand with air nippers performance and durability.

Contek India are one of the Best Aire Nipper Manufacturers, Suppliers and Exporters in India, We designed customized product with effective, functional and efficient air nipping sytems solutions appropriate for your business. From overall support hand tools to full robotic integration, our company is flexible and quality your installation demands. An investment in high tech, reduced downtime operation, and increased performance is built into the purchase of our Air Nippers. Full support is also provided with the addition of air compressor spare parts and modular sliding supports for utmost utilization.Contact us today

FAQ

A suction cup works by the cup being put on a flat, smooth area to push the air out from under it and create a vacuum or area of low pressure. The surrounding atmospheric pressure is higher on the outside and will adhere tightly to the cup on the surface.

Suction cups temporarily hold things onto flat surfaces like glass, tile, or metal without the use of screws or adhesive. They work well in the bathroom, kitchen, car, and even industrial cranes.

The basic function of a suction cup is to achieve a strong grasp on flat surfaces via air pressure. The grasp allows it to suspend or hold objects without in any way damaging the surface.

The suction cup operates on pressure difference—by removing air underneath the cup, the space below is left at lower pressure, and the greater external air pressure forces the cup down against the surface. The pressure difference holds the suction cup in place until air moves back in.