End of Arm Tool

End of Arm Tool Manufacturers in Pune, EOAT Tooling Suppliers and Exsporters in Pune

Contek is one of the leading End of Arm Tool (EOAT) manufacturers, suppliers and exporters based in Pune, Delivering customizable, long-durable & high-precision for quality handling of product. Our EOAT solutions are framed in accordance with the needs of industries today that utilize robotics because they are flexible, precise, and faster. Whether you need to make generic tooling or tailor-made robotic grippers, Our company is dedicated to providing solutions that are tailor-made to your manufacturing objectives.

EOAT - End of Arm Tool Manufacturers in Pune

We think robotic efficiency is not any better than the attached tools themselves, and therefore our EOAT solutions are designed for highest performance as well as expandability for the future. Being the robotic tooling experts, we not only keep up with the current industrial trends and robotic integration standards but enhance them rather. Our tools are add-ons only in the sense that they become necessities for smarter production process.

Types of End of Arm Tooling (EOAT)

A well-known End of Arm Tooling manufacturers in Pune (EOAT), We are providing the best quality of End of Arm Tooling such as:

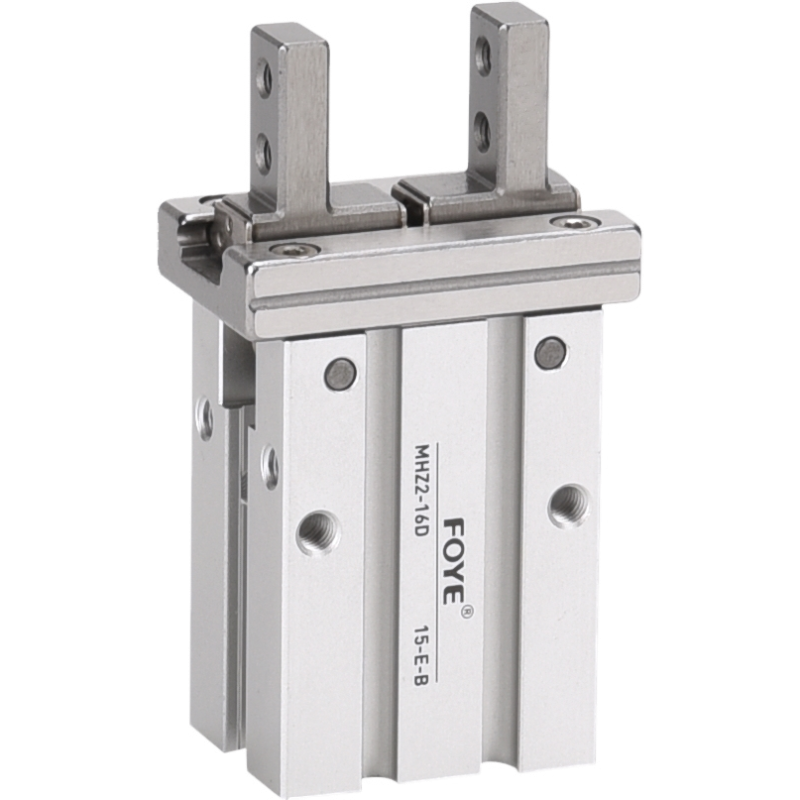

1. Grippers (Mechanical, Pneumatic & Vacuum):

| Specification | Details |

|---|---|

| Type | Mechanical, Pneumatic, Vacuum |

| Grip Force Range | 5–200 N (Adjustable) |

| Material Compatibility | Fragile, Rigid, Irregular Shapes |

| Sensing Technology | Force sensors & Soft-touch units |

| Operating Pressure | 4–6 bar (Pneumatic models) |

We provide different types of grippers that perform pick-and-place functions with reasonable consistency and least wear. Our smart mechanical and vacuum grippers incorporate sophisticated sensing technology to conform to the shape and weight of various products. The grippers are now supplied with force-sensing technology and soft-touch controlling units to pack fragile products securely without shattering

2. Welding EOATs:

| Specification | Details |

|---|---|

| Welding Type | MIG, TIG, Spot Welding |

| Precision Tolerance | ±0.05 mm |

| Quality Monitoring | Real-time with diagnostics |

| Application Industries | Automotive, Aerospace, Metal Fabrication |

| Cooling Mechanism | Integrated air/liquid cooling |

Welding EOATs: Our material removal tools have widespread applications in the metal and automotive industries where precision and speed must be utmost priority. We utilize our material removal EOATs with on-line quality monitoring to minimize quality and errors to zero level for mass run production. Our tools assure precise material removals in each operation with automated alignment and diagnostic functions.

3. Material Removal Tools:

| Specification | Details |

|---|---|

| Operations | Cutting, Grinding, Deburring, Polishing |

| Speed Range | 5,000–25,000 RPM |

| Feedback System | Real-time force & resistance tracking |

| Noise Level | < 70 dB |

| Material Suitability | Metals, Plastics, Composites |

Material Removal Tools: These instruments are used in multiple types of applications such as cutting, deburring, grinding, and polishing where material removal with accuracy and delicacy is required. Our instruments are now equipped with intelligent force management systems that automatically adjust with real-time feedback depending on the resistive and densification characteristics of the material. We also design them to minimize vibration and noise levels to produce a more secure and productive working environment.

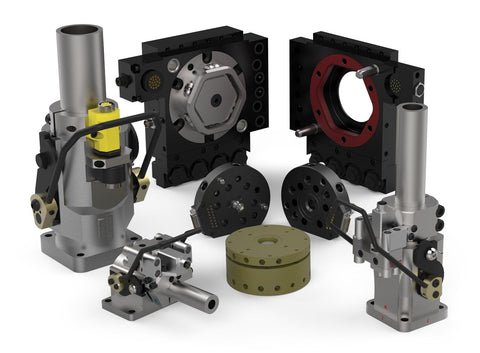

4. Multi-Tool Changers:

| Specification | Details |

|---|---|

| Tool Recognition | Auto-ID via RFID/NFC |

| Switching Time | < 3 seconds |

| Payload Capacity | Up to 50 kg |

| Communication Protocol | Ethernet/IP, Profinet, IO-Link |

| Supported Tools | Grippers, Welders, Sensors, Polishers |

Multi-Tool Changers: Our tool changers enable the robots to transition from one EOAT to another on their own, reducing much time and man-hours. These now include automatic tool recognition functions that detect each attachment and configure the system accordingly based on identification. This makes them perfect for multi-purpose manufacturing lines where one robot will perform several tasks

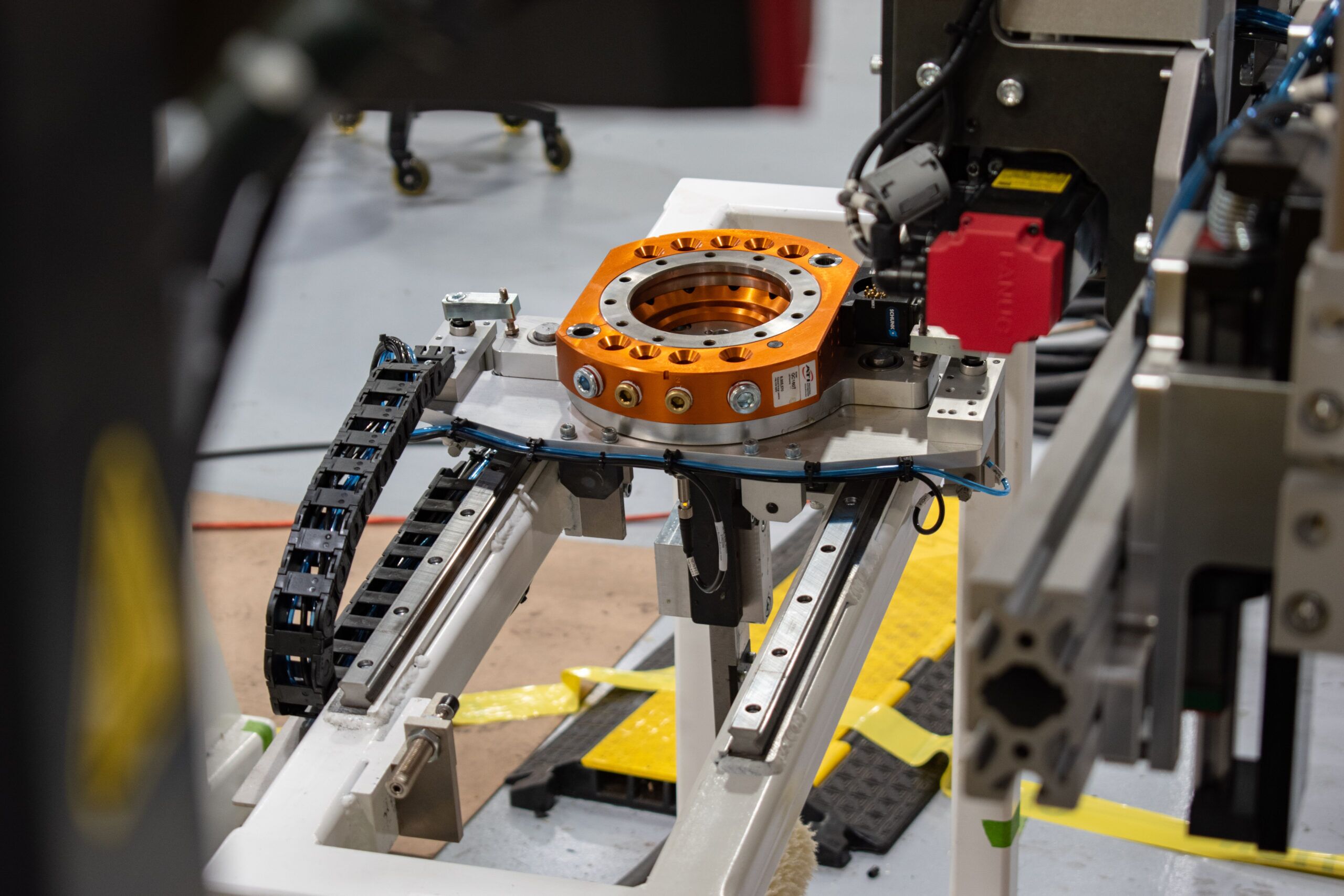

5. Custom Robotic Tooling:

| Specification | Details |

|---|---|

| Material Used | Carbon Fiber, Aluminum Alloys |

| Simulation Software | CAD, FEA, Motion Analysis Tools |

| Integration Support | On-site + Virtual Simulation |

| Max Payload Optimized | Up to 30% lighter than standard EOATs |

| Industries Served | Pharma, Electronics, Aerospace, FMCG |

Custom Robotic Tooling: We manufacture and design full custom EOATs to your project requirements and industrial uses. Our custom products incorporate light-weight, high-strength materials like carbon fiber and advanced composites in order to minimize robotic payload. Advanced 3D simulation and modeling are also utilized during the design for enhanced effective integration and performance.

Key Features of End of Arm Tool (EOAT) Solutions

One of the leading End of Arm Tool (EOAT) suppliers in Pune, our all-types of End of Arm Tool (EOAT) are included with new technological formulations such as:

- Increased Modularity: We design our EOATs with modular construction so that it becomes simple to swap or upgrade components without replacing them entirely. Such an advantage gives simplicity in day-to-day tool change to new applications or for compatibility with newer robot arms. Your manufacturing is future-proofed with minimal extra investment with modularity.

- Plug and Play Integration: All of our EOATs are pre-wired for rapid mounting with little programming or setup time necessary. They may be simply mounted on any robotic arm type with standard connectors and mounting arrangements. This lowers integration expense as well as accelerating deployment onto the factory floor.

- Smart Sensor Compatibility: We incorporate object presence sensors, pressure sensors, and real-time grip force measurement. These intelligent features allow the robots to respond immediately if anything unusual happens, for optimal process control and safety. It also allows problem-free data logging for analysis and preventive maintenance planning.

- Lightweight and Durable Structure: Our EOAT is constructed using high-grade metals and engineered polymers that give the strength without accessorizing too much weight in the robot arm. This is crucially important in terms of speed performance as well as minimizing the wear and tear of robotic joints in the long run. We employ corrosion-resistant material to ensure extended reliability even for aggressive environments.

Advantages of End of Arm Tooling (EOAT)

Our all types of new End of Arm Tooling Company in Pune gives various types of benefits such as:

- Improved Automation Efficiency: Our EOATs enable robot cells to do repetitive tasks quicker and more accurately than the human hand. That is more throughput and uniform product quality shift after shift. You have the option to add real-time monitoring and process optimization, providing you with greater control of your automation environment.

- Less Maintenance Required: We build our EOATs with strong internal mechanisms and long-lasting components that need very little maintenance. Self-cleaning devices and housings that seal in are included on most of our tools to avoid dust or debris affecting performance. This avoids unexpected downtime and lowers overall maintenance costs.

- Enhanced Workplace Safety: By being capable of managing hazardous, heavy, or delicate products, our EOATs minimize human intervention in hazardous processes. We create safety-oriented modules like overload sensing and stop trigger mechanisms to make the automation process safe for machines as well as human beings. This lowers on-site injury to a great extent and makes it regulatory compliant.

- Multi-Functionality and Flexibility: With a single robotic setup, supported by our EOATs, the whole range of operations can be achieved with multi-tool and high-speed change capability. Various product lines can be handled by manufacturers with a single robotic investment because of such flexibility. It makes your automation setup easy for both.

Applications of our End of Arm Tooling

Being the best Robotic Gripper Manufacturers in Pune, our all types of End of Arm Tooling are included with new feature and highly used in multiple applications such as:

- Pharmaceutical and Medical Industries: We supply EOATs precision-made and sterilized for drug handling and laboratory automation. They are resistant to chemicals and meet hygiene standards, easy to clean and convenient. They enable inspection, sorting, and packaging of medical products.

- Electronics and Semiconductor Industry: We produce high accuracy EOATs with extremely light grippers for fragile electronic parts and microchips. Such equipment function in cleanrooms and are constructed with anti-static features so as not to harm the components. They possess high accuracy and gentle touch and are able to handle intricate parts.

- Packaging and Logistics: Our EOATs are used for a range of applications in palletizing, product labelling, case packing, and sorting machines. Our machines are installed with vacuum and mechanical grippers that change to fit the product's size and shape. Our machines increase packaging speed with minimal amounts of waste. Our machines also optimize warehouse operations with automated placement and picking.

- Automotive Industry: We provide EOATs for painting, welding, assembly, and component handling in auto production facilities. It can withstand harsh operating conditions and is intended for high-cycle use. Its accuracy produces tighter tolerances and better quality assemblies.

Contek is one of the Best End of arm tool manufacturers, suppliers and exporters in Pune, offering the best quality of end arm tooling, We work alongside customers, not merely supplying equipment we help them leverage their automation potential with customized, proven, forward-looking tooling. Each EOAT we supply demonstrates our dedication to innovation, quality, and enduring value

We invite you to browse our full range of robotic end of arm tooling, which will elevate your production to new heights. Expanding or optimizing, we have the best EOAT that will suit your vision. Contact us today for more information

FAQ

It's the tool at the end of a robot arm that touches pieces or tools in automation.

Grippers, vacuum cups, magnetic tooling, and welding torches are common EOATs.

The selection depends on the task, object material, size, weight, and precision required.

Actually, EOATs can be specially made for single applications to maximize performance and efficiency.