Aluminium Extrusion

Aluminium Extrusion Manufacturers in Inida, Suppliers and Exporters in India

Contek India is one of the dominant Aluminium extrusion manufacturers, suppliers and exporters in India, We are offering the high quality, High Thermal & Electrical Conductivity of aluminium extrusion, With our best manufacturing centers backed by in-house die design centers, we stand ready to serve a myriad of industries with unprecedented efficiency.

We offer anything from a plain profile to complex, custom-made extrusions to international levels of quality and performance. Our advanced manufacturing and eco-friendly practice being the fulcrum point, we strive to serve those industries that need strength, precision, and design flexibility. In applications as required, whatever you are designing for strength, structure, or ornamentation, our aluminum extrusions are made to provide maximum possible performance in application

Types of Aluminum Extrusion

A well-known Aluminum Extrusion manufactures in India, We are providing the best quality of Aluminum Extrusions such as:

Square Aluminum Extrusions

We offer accurate Square Aluminum Extrusions commonly used in architectural, structural, and fabrication applications. Extrusions are so made that they offer higher load carrying capacity with accuracy for larger spans. We also offer sophisticated types with anodized finish to offer additional corrosion resistance and polish finish suitable for modern architectural systems and heavy duty applications as well.

| Specification | Details |

|---|---|

| Material Grade | 6061-T6 / 6082-T6 |

| Cross-Section Size | 20 mm × 20 mm to 150 mm × 150 mm |

| Surface Finish | Mill, Anodized, Powder Coated |

| Wall Thickness | 1 mm to 6 mm |

| Application Use | Architecture, Framing, Fabrication |

T-Profile Industrial Aluminum Extrusion

Our Industrial T-Profile Aluminum Extrusions are designed particularly for assembly line building modules, automation centers, and manufacturing facilities. The profiles seamlessly fit into kinetic structures such as robotic installations, workstations, and conveyor systems. Our T-Profiles, featuring best integrations, can handle greater torque, and they can be fast installed and reconfigurable without weakening the structure.

| Specification | Details |

|---|---|

| Material Composition | 6063-T5 Aluminum Alloy |

| Profile Type | Industrial T-Slot |

| Tensile Strength | ≥ 190 MPa |

| Modular Compatibility | 20, 30, 40, 45, 60 mm Series |

| Assembly Integration | Quick-fit with Standard Connectors |

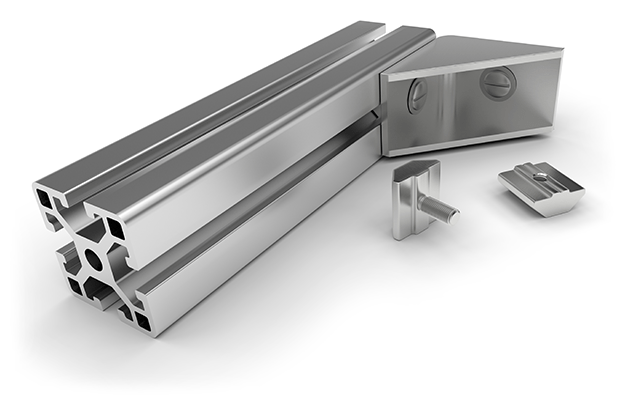

Square T Slotted Aluminum Extrusion

We produce Square T Slotted Aluminium Extrusions that are very versatile to fit test equipment enclosures, machine enclosures, laboratory hardware, and cleanroom. T-slotted design also benefits with the re-locatable rigid mounting of connections with or without welding and specialized high-tech hardware. Our newer designs also feature improved anti-vibration grooves and surface treatment processes that provide enhanced durability and performance in rugged industrial applications.

| Specification | Details |

|---|---|

| Groove Width | Standard 6 mm, 8 mm, 10 mm |

| Profile Dimensions | 20×20, 40×40, 45×45 mm & Custom Sizes |

| Surface Treatment | Anodized / Brushed / Sandblasted |

| Vibration Resistance | Enhanced Grooves with Damping Features |

| Application Scope | Cleanrooms, Lab Rigs, Machine Frames |

Aluminium Extrusion Profile (Custom & Standard)

From simple bar to full custom complex profile, we stock Aluminium Extrusion Profiles of superior quality. We extrude all the profiles with the help of best Aluminium Extrusion Dies in-house designed and developed by us on CNC precision for an ideal shape tolerance and surface finish. From aerospace to consumer electronics to any business that needs high precision and innovation, our ability to deliver precision-engineered custom profiles makes us a credible business partner to segments of the industry needing high precision and sizes of innovation.

| Specification | Details |

|---|---|

| Die Customization | CNC Machined, In-House Designed |

| Tolerance Level | ±0.05 mm |

| Length Availability | Up to 6 meters |

| Industries Served | Aerospace, Electronics, Defense, OEMs |

| Profile Type Range | Flat Bars, Channels, Tubes, Complex |

Key Features of Aluminum Extrusions

One of the leading Aluminum Extrusions suppliers in India, our all-types of Aluminum Extrusions are included with new technological formulations such as:

- High Precision Dies: Our High Precision Die aluminum extrusion makes each profile as good as the last one. Supported by best generation CNC machines, we develop tight tolerances to keep rejection to an all-time minimum and optimize assembly efficiency to best abilities. Our dies are continuously updated by keeping clients' suggestions and project requisites in mind to operate at the highest level on very specialized products.

- Advanced Surface Treatment: We offer various surface finishes like anodizing, powder coating, and brushing to address functional as well as aesthetic needs. These are corrosion-protected and give a high-end look to every profile. Long-profiles are also made easy to finish with reduced post-processing by our technology for customers' processes.

- Lightweight But Strong: Our extrusions provide the best balance of strength and weight and are thus best suited for use where efficiency and energy performance are top priorities. We employ the most advanced technology of aluminum alloys that are incredibly strong without added weight. This is of ultimate importance in the aerospace and electric car industry where grams make a difference.

- Sustainability-Driven Production: Our green production is on the sustainability platform, and we utilize all resources to minimize the environmental impact. We employ energy-efficient extrusion techniques and recycle nearly 100% of the scrap aluminum material that is generated in the process. Our green production concept not only lowers our carbon footprint but is also part of the global efforts towards sustainability in industries.

Benefits of Aluminum Extrusions

Our all types of new Aluminum Extrusions provides multiple types of benefits such as:

- Design flexibility: We can create profiles of complex geometry with the least end-user assembly parts to a bare minimum. We give designers and engineers the liberty of designing uncompromisingly in the path of conventional manufacturing. Your need is channels combined, fastener grooves, or multi-cavities unit, we deliver it in readily available forms.

- Cost-Efficiency: Our design is an expediency and material conservatism design with immediate transfer to cost of production reduction. We use quick-change tooling, and we minimize waste using intelligent die design and material management. This positions our extrusions in the best possible condition for small-run protoqing and volume production.

- Thermal & Electrical Conductivity: Aluminum is inherently conductive, and our specialty profiles are designed specifically to yield the highest thermal as well as electrical efficiency in an application. LED lighting heat sinks, power enclosures, and EV battery enclosures are a few of the uses. Our extrusions achieve maximum performance and reliability in aggressive electronic assemblies.

- Corrosion Resistance: We offer profiles with protective coating and finish that have the ability to prolong strength even with adverse weather and industrial use. That is highly beneficial in our outdoor marine, coast, and construction building. They achieve their lifespan through being highly prolonged with little or no maintenance.

- Tech-Enabled Customization: We utilize the latest computer design software and simulation tools to design and refine profiles prior to production. CAD-CAM application in our company supports us in rapid prototyping, hence enabling us to respond to design changes and custom orders on a flexible scale. It is due to such technology-driven mechanism that accuracy, speed, and efficiency are ensured at every phase.

Applications of our Aluminum Extrusions

Being the best Aluminum Extrusions exporters in India, our all types of Aluminum Extrusion are included with new feature and highly used in multiple applications such as:

- Industrial Automation: We offer T-Slot and Square T-Slotted Aluminum Extrusions built into machine frames, guards, conveyors, and bases and are reassembled and reconfigurable with minimal effort. The modular design of the profile offers flexible manufacturing lines with the ability to rebalance themselves in an attempt to adjust to changing demands of production. Our extrusions introduce automation installations with consistent high carrying capacity and vibration damping capacity.

- Construction & Architecture: We provide aluminum profiles for contemporary architectural details like window frames, curtain walls, canopies, and partitions. The aluminum used is lightweight, installable, and simple yet provides additional strength to the structures. Our profiles also include innovative coatings and design aspects that provide energy efficiency as well as beauty if applied in residential or commercial structures.

- Electric Vehicles & Automotive: Our profiles are employed in EV body parts, crash protection systems, battery case covers, and light bracketry employed in the manufacture of cars as light as possible. With increased focus on efficiency and sustainability, aluminum is increasingly being employed as the ultimate metal to design new cars. We are collaborating with EV producers to supply profiles that will be capable of fulfilling the safety, strength, and electrical insulation requirements.

- Electronics & Lighting: We manufacture heat sinks, enclosures, and heat dissipation controlling mounting profiles for small electrical devices and light installations. Our extrusions are manufactured to be used in LED installations where heat is most effective in performance and longevity. Our profiles, having smooth finishes and near-tolerance tolerances, are ready to be installed directly into consumer products.

Contek India is one of the premier Aluminium Extrusion Manufacturers, Suppliers and Exporters based in India. We offer 100% Recyclable & Eco-Friendly, high quality of Aluminium extrusion at latest affordable prices in india as per the customers need. From constructing buildings to high-performance EV components, our profiles are shaping the pillars of modern engineering. We also utilize our technology and design expertise to fit emerging standards and capitalize on requirements. With a focus on quality, custom, and timely delivery, we're here to help with your most challenging aluminum extrusion needs. Step on in and take advantage of the actual value of specialty manufacture with back-end support of cutting-edge technology. Contact us today for more information!

FAQ

Aluminium extrusion is a manufacturing process where heated aluminium is pushed through a shaped die to create profiles used in frames, supports, and enclosures.

The process works by heating an aluminium billet, forcing it through a die under high pressure, and then cooling and cutting it into desired lengths.

The key steps are:

1. Preparing the billet – heating the aluminium log

2. Extrusion – pushing the billet through the die

3. Quenching – rapidly cooling the extruded shape

4. Stretching – straightening and aligning the profile

5. Cutting and aging – cutting to length and heat-treating for strength.