Gripper

Gripper Manufacturers in Pune - Robotic Gripper Company Pune

Contek India is a best gripper manufacturers, suppliers and exporters in Pune, are experts in developing and designing high-performance industrial automation grippers as per the customers requirement. We have decades of experience and innovation tradition to serve industries ranging from robots to packaging and automotive. Our grippers are designed to provide precision, power, and economy in the most challenging applications. We set the pace by integrating intelligent technologies and flexible functions in all our solutions. Pneumatic to hydraulic to magnetic systems, we have everything in our product line that anyone may need.

Types of Grippers

A well-known Gripper manufacturers in Pune, We are providing the best quality of Grippers such as:

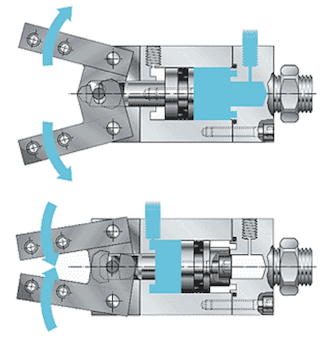

1. Pneumatic Gripper

We produce high-speed pneumatic grippers with repeatable and real-time clamping force in robot-based production lines. Recent designs feature flow control valves, which save air consumption and ensure maximum energy efficiency. The grippers are highly suitable for repetitive applications where accuracy and speed are paramount.

| Specification | Details |

|---|---|

| IoT Compatibility | Sensor & Data Feedback Enabled |

| Adjustment Mode | Auto reconfiguration by object size |

| Gripper Weight | 500g – 1.2kg |

| Control Interface | Ethernet/IP, Modbus |

| Applications | Pick-and-place, Sorting, Assembly |

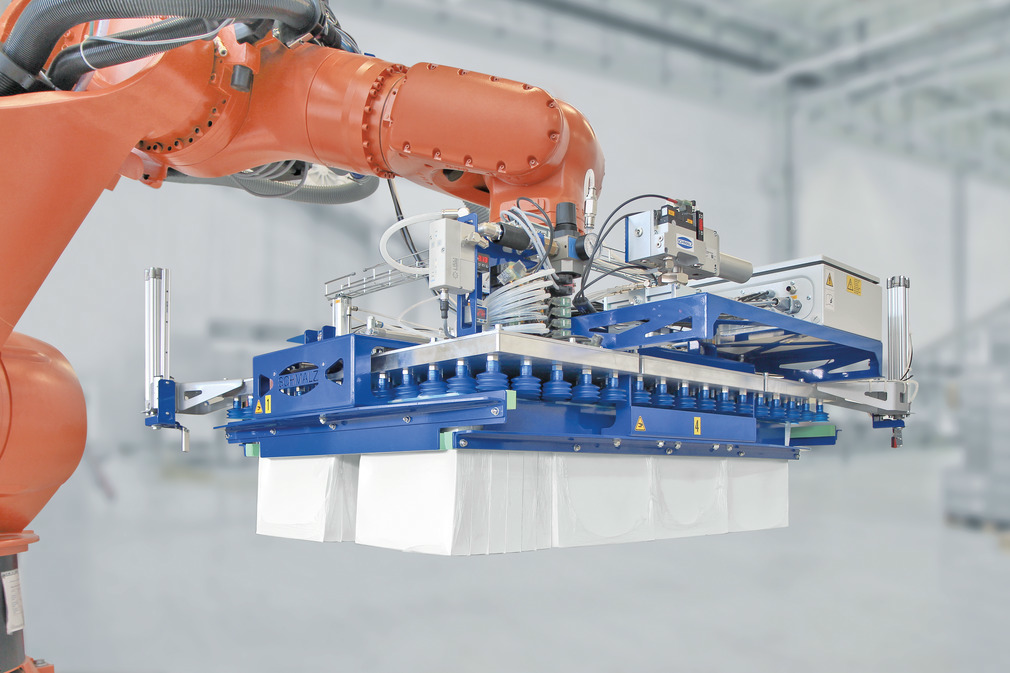

2. Robotic Gripper

Our grippers are designed to work in ideal harmony with industrial robots. They are IoT sensor compliant and reconfigurable grip mechanisms, and provide real-time feedback and reconfigure based on object size and type. Our grippers support smooth pick-and-place, sorting, and high-precision assembly.

| Specification | Details |

|---|---|

| IoT Compatibility | Sensor & Data Feedback Enabled |

| Adjustment Mode | Auto reconfiguration by object size |

| Gripper Weight | 500g – 1.2kg |

| Control Interface | Ethernet/IP, Modbus |

| Applications | Pick-and-place, Sorting, Assembly |

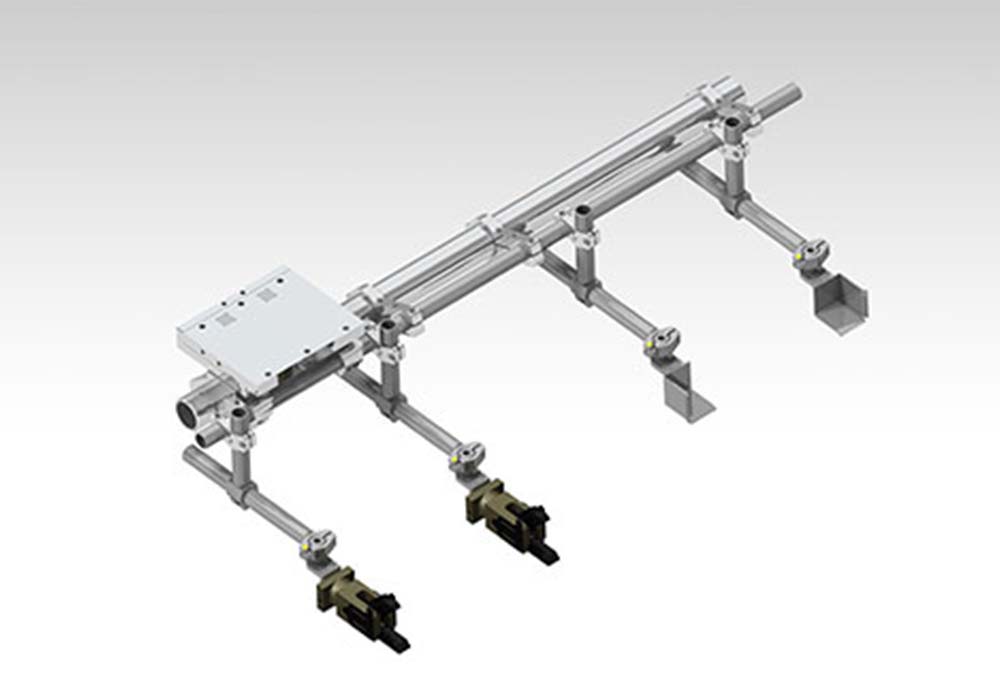

3. Vacuum Grippers

Our vacuum grippers are designed to pick flat, irregularly shaped, or fragile material with little physical contact. With inbuilt best suction control mechanisms and pressure configurable control, they ensure robust gripping with reduced chances of damage. They have vast usage in the packing, electronics, and textiles industries for safe handling and efficient processing.

| Specification | Details |

|---|---|

| Vacuum Level | Up to -90 kPa |

| Compatible Surfaces | Flat, Irregular, Fragile |

| Suction Type | Centralized / Decentralized |

| Control Feature | Adjustable suction & pressure feedback |

| Material Contact Safety | Non-marking, gentle grip |

4. Magnetic Gripper & Standard SGM Magnetic Grippers

We provide general-purpose and standard SGM magnetic grippers for safe and non-contact handling of ferrous components without touching or marking. They possess permanent quality magnets and instant release, and are intended for CNC milling, car part lifting, and robot automatic line. The grippers are instant and clean with zero possibility of contamination.

| Specification | Details |

|---|---|

| Magnet Type | Permanent Rare-Earth Magnet |

| Holding Force | Up to 150 N |

| Release System | Instant Pneumatic or Manual |

| Contamination Risk | Zero Contact Contamination |

| Usage Areas | CNC, Robotics, Ferrous Lifting |

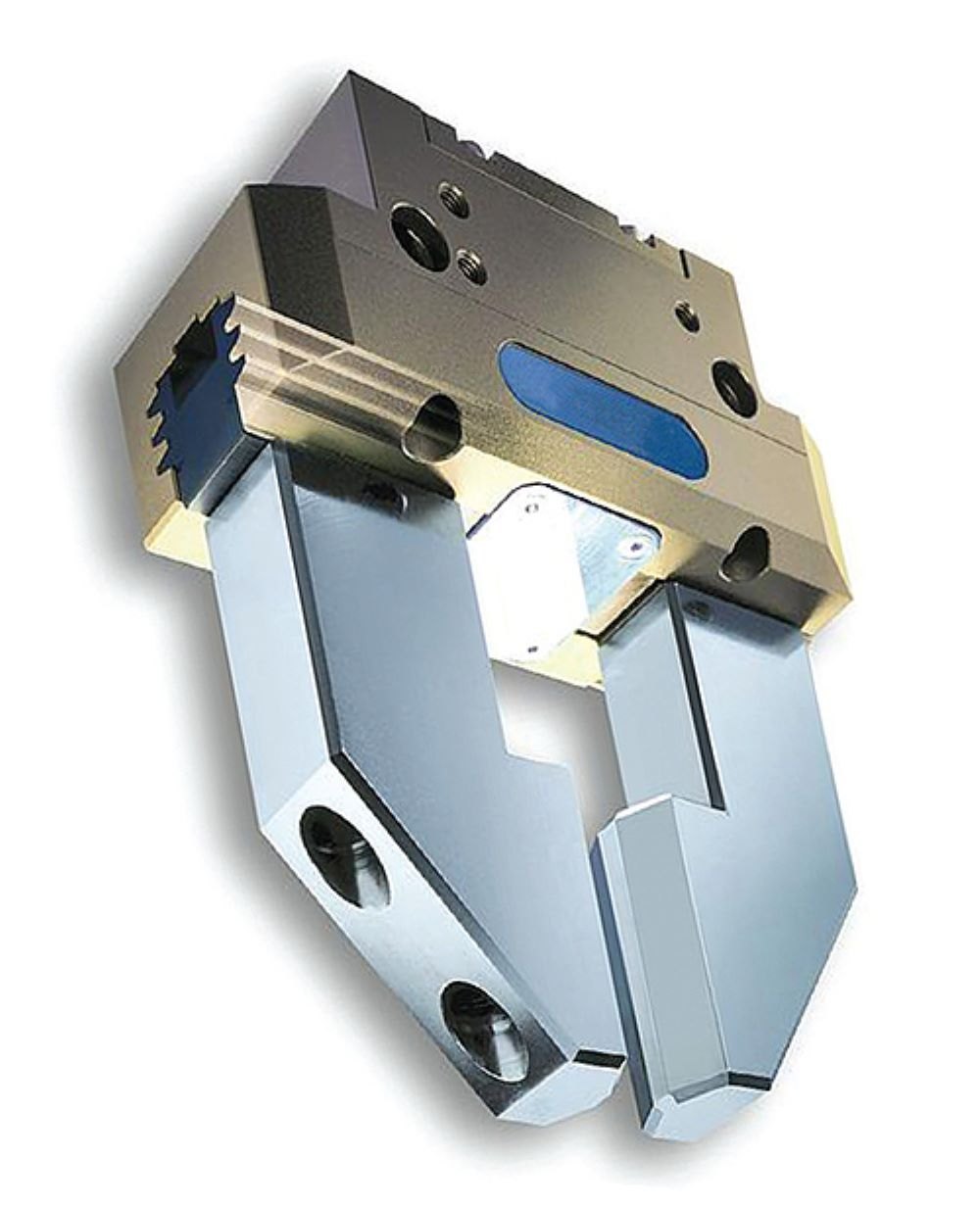

5. Parallel Grippers

Our parallel grippers are high-force grip and space-saving, thus best for demanding and precise applications and efficiency in saving space. Their real-time position feed-back capacity as well as stroke lengths adjustability makes them used extensively in manufacturing processes. The single-direction grip at both sides of a component is the one that provides the balanced control as well as spares components from wear.

| Specification | Details |

|---|---|

| Stroke Length | 5–25 mm (adjustable) |

| Position Feedback | Encoder/Sensor Based |

| Holding Force | Up to 300 N |

| Mounting Orientation | Any |

| Application Type | Precision Manufacturing |

6. Hydraulic Gripper System

We manufacture heavy industry high-pressure hydraulic grippers with good and stable pressure grip. They have adjustable pressure control levels, whose pressure grip may be adjusted by operators according to the operation. They are extensively applied in automobile production, steel processing, and heavy industrial machinery

| Specification | Details |

|---|---|

| Hydraulic Pressure | 5–30 MPa |

| Gripping Capacity | Up to 1000 N |

| Adjustment Mechanism | Manual / Electronic Control Valve |

| Construction Material | Hardened Steel or Alloy |

| Application Fields | Automotive, Steel, Heavy Machinery |

7. Hand Gripper

We manufacture ergonomic and light-weighted hand grippers that are both personal use environments like strength training as well as rehabilitation center installations. The designs feature anti-fatigue grip as well as additional mechanical leverage for simple use. They are generally used in medical therapy departments, fitness training gyms, and field test laboratories.

| Specification | Details |

|---|---|

| Weight | < 250g |

| Resistance Range | 10–60 kg |

| Grip Material | Anti-slip Rubber |

| Application Areas | Fitness, Medical Rehab |

| Handle Type | Ergonomic, Shock-absorbing |

8. Stainless Steel Pneumatic Gripper

Our stainless steel pneumatic grippers are designed specifically to meet the tough hygienic and corrosion-resistant applications such as food processing and pharmaceutical. The grippers are made with smooth surface and closed design to allow wash-down compatibility and contaminant-free operation. The grippers are made to ensure maximum long-lasting performance despite humid or chemical-exposed applications.

| Specification | Details |

|---|---|

| Material | Stainless Steel 304/316 |

| Surface Finish | Smooth, Wash-down Safe |

| Corrosion Resistance | High (Food & Pharma Grade) |

| Sealing Standard | IP67/IP69K |

| Industries | Food, Pharma, |

9. Mild Steel Handling Gripper

We produce long-lasting and cost-effective mild steel material handling grippers for general industrial and medium-duty material handling purposes. They come with coatings such as zinc plating to give additional long life and corrosion resistance. They are best used in sheet metal fabrication, warehouse systems, and manufacturing plants where dependability is required.

| Specification | Details |

|---|---|

| Frame Material | Mild Steel |

| Surface Coating | Zinc Plated / Powder Coated |

| Load Capacity | Up to 75 kg |

| Typical Use | Warehouse, Fabrication, Assembly |

| Grip Style | Mechanical |

Key Features of Grippers

A dominant Gripper suppliers in Pune, our all types of new Grippers are filled with new features inside such as:

- Smart Sensor Integration: We employ smart sensor systems, which offer feedthrough of object position, grip force, and operation failure to increase automation accuracy and reliability. Sensors prevent damage and enable early detection of wear and tear. It also offers smooth machine interaction and quick adjustment.

- Modular Designs: Modular design is integrated into all of our grippers to provide easy assembly, hassle-free performance, and tool-free component replacement. The design supports robot arm compatibility, end-effector compatibility, and controller compatibility. It helps in saving time for system refurbishment or production configuration adjustment.

- Surface-Adaptive Gripping: Our systems adapt to changing object surfaces smooth, textured, or sensitive material. It provides a firm hold with no object damage for objects of any size and texture. It is particularly well suited to applications like glass handling, electronics, and sensitive packaging.

- Energy-Efficient Construction: We aim to design grippers with reduced compressed air, electricity, or hydraulic fluid usage without compromising their strength and performance. Design control and features are optimized to provide lower cost of operation and eco-friendly automation. This is along with the vision of new factories for sustainability.

- Light Weight but Robust Materials: We implement quality stainless steel, aluminium alloys, and engineered polymers that provide strength with reduced weight and corrosion resistance. This adds speed and flexibility to the robotic arm without overburdening them. It also assists in prolonging the lifecycle and minimizing wear.

Benefit of Grippers

These all types of our Grippers gives various types of benefits such as:

- More Productivity: Designed to provide maximum speed and efficiency to your operations, these grippers minimize cycle times and increase throughput. Installed in stand-alone equipment or on advanced automation lines, they ensure consistent and rapid processing. This implies greater aggregate production capacity and increased ROI.

- Higher Precision: Our specially crafted products do away with misalignment and grip variation, which means that each piece is processed with fine control. This instantaneously minimizes wastage and enhances end-product quality. It's particularly important in those fields where micro-tolerance is a major concern, including aerospace and electronics.

- Industry Flexibility: We have a very wide spectrum of products for application in many industries such as auto, foods and beverages, pharmaceuticals, aerospace, packaging, electronics, etc. Every gripper is designed to the performance and environment specifications of their respective industries. Special operations or specialty operations can be customized as well.

- Fewer Down Times: With our grippers that implement predictive maintenance, sophisticated diagnostics, and rugged construction, your equipment achieves more runs with fewer downtimes. Rapid service capabilities and convenient access to spare parts further reduce machine downtime. That means fewer plant shutdowns and reduced repair expense.

Applicationsof Grippers

Being the best Gripper exporters in Pune, our all types of Grippers are included with new feature and highly used in multiple applications such as:

- Logistics & Packaging: Our parallel and pneumatic grippers facilitate high-speed picking, sorting, and packaging processes in modern warehouses and distribution centers. Our grippers are utilized in box filling and conveyor systems for cartons and logistics conveyor systems with high efficiency. They have extremely high reliability and work properly with constant load.

- Automotive: We provide robotic and magnetic grippers to be used for large body part transfer, assembly tasks, and welding lines. Our grippers mechanize basic operations and deliver repeatable alignment and quality. They are a critical element in robotic arms for inspection, painting, and part transfer.

- Pharmaceuticals & Food Processing: We offer cleanroom- and hygiene-approved vacuum grippers and stainless steel grippers that offer contamination-free picking and handling. The grippers ensure safe processing of delicate products such as drugs, laboratory samples, and food items. The grippers are wash-down designed to offer ease in maintenance under harsh conditions.

- Electronics Assembly: Mini grippers and magnetic grippers are meant for accurate micro-component placements like circuit boards, chips, and connectors. They are non-intrusive and static-protective and therefore very well-suited for ESD-sensitive environments. They are generally shared among SMT lines and mobile assembly plants.

- Defense & Aerospace: Provide hydraulic and parallel grippers that possess the ability to grasp specialty parts with strength and accuracy to suit heavy-load applications. They are utilized in assembly of aircraft components, missile components, and heavy-duty defense-equipment components. Their robust performance in extreme conditions makes them extremely valuable.

Contek India is One of the best Gripper manufacturers, suppliers and exporters in Pune, We are capable to design and produce top-class grippers for industrial automation, With decades of legacy and passion for innovation, we offer solutions to sectors such as robotics, packaging, and automotive. Our grippers are precision-made to be precise, dependable, and effective in even the most demanding applications. We keep extending the boundaries with innovation by incorporating intelligent technologies and adaptive functionality in all our products. From pneumatic through hydraulic to magnetic solutions, our portfolio of products has a solution for all applications. Contact us today for more information.

FAQ

Pneumatic grippers use compressed air for rapid grasping power, while electric grippers offer precise control and programmability for less upkeep.

The automotive industry uses parallel, angular, vacuum, and magnetic grippers for part handling, assembly, and welding operations.

Refer to areas like payload, object shape, precision needed, operating environment, and system compatibility with the robot control system.

A gripper is a robotic end-effector that grasps and manipulates objects typical of manufacturing, packaging, and assembly automation.