Modular Conveyor

Modular Conveyour Manufacturers, Suppliers and Exporters in Pune

Contek is leading Modular Conveyor manufacturers, suppliers and exporters in Pune. Our equipment is engineered with a top priority on innovation, efficiency, and flexibility to serve next-industrialization needs. From delicate food products or massive-truck parts, our conveyors are designed to work reliably. With our enhanced engineers and creative minds, we produce products that turn out to be durable. We design all the systems we build modular, expandable, and automation-friendly. We blend industry experience and leading technology to transform material flow in your factory.

Types of Modular Conveyor

One of the leading Modular Conveyor manufacturers in Pune, our all-types of Modular Conveyor are included with new technological formulations such as:

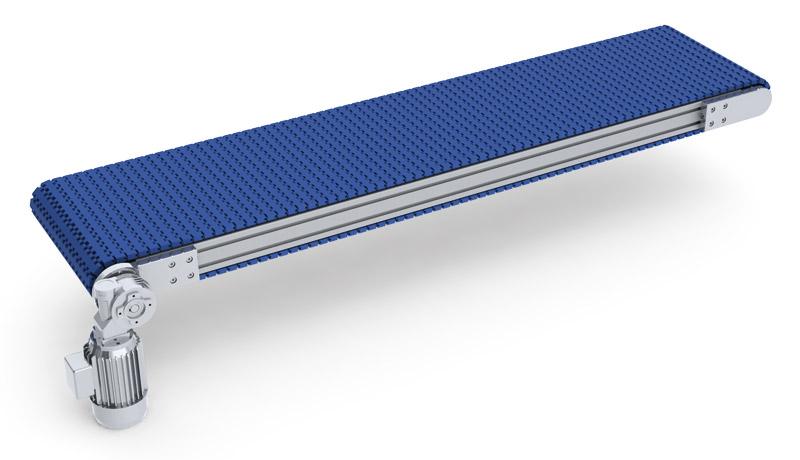

Straight Modular Belt Conveyors

We manufacture straight modular conveyors suitable for transporting goods in a straight line with highest stability. The systems consist of robust plastic modular belts of food-grade material with heavy load capacity and long lifespan. Either in packaging lines or food processing, the conveyors have high levels of hygiene and performance with little need for maintenance.

| Specification | Details |

|---|---|

| Belt Material | Food-Grade Plastic (PP/Acetal) |

| Structure Frame | Stainless Steel or Powder-Coated Steel |

| Load Capacity | Up to 100 kg/m² |

| Belt Width Range | 200 mm to 1200 mm |

| Ideal Applications | Food Processing, Packaging Lines |

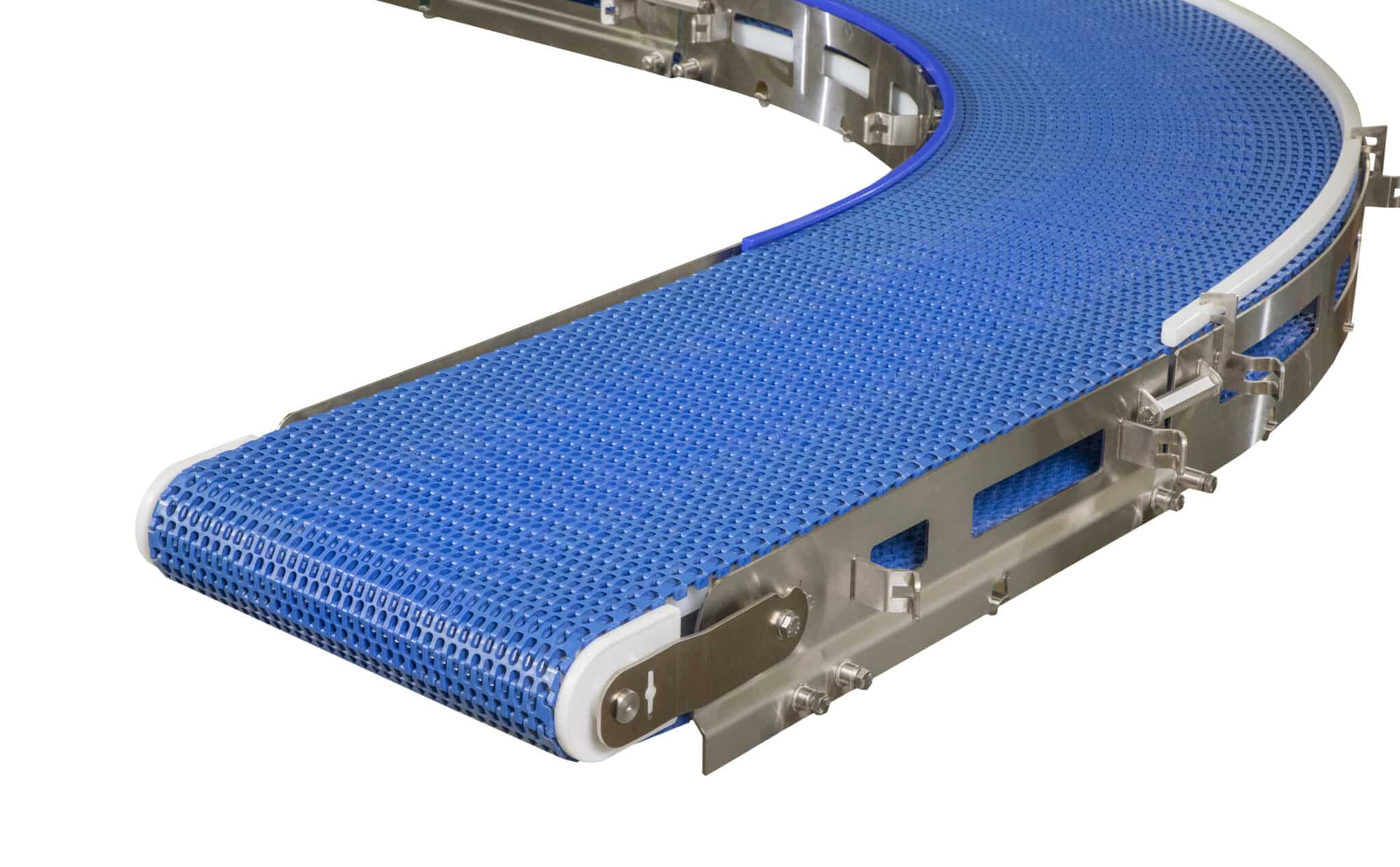

Curved Modular Conveyors

Our bending modular conveyors enable businesses to use less available floor space. They have radius-friendly modular belts that travel smoothly over direction changes without compromising product orientation or speed. These conveyors are typically utilized in small manufacturing areas and packaging lines where space is scarce.

| Specification | Details |

|---|---|

| Curve Angles Available | 30°, 45°, 60°, 90°, 180° |

| Belt Type | Radius-Optimized Modular Plastic |

| Outer Radius | 500 mm to 1200 mm |

| Speed Capacity | Up to 40 m/min |

| Usage Area | Space-Saving Packaging/Assembly Lines |

Inclined/Declined Modular Belt Conveyors

We offer inclined or declined modular conveyor systems for vertical transfer of products. They have gripping surfaces and cleated modular belts to prevent slippage and provide safe, controlled material handling. They serve the purpose in assembly lines and packaging stations where elevation transfer is required.

| Specification | Details |

|---|---|

| Inclination Angle | 10° to 45° |

| Belt Type | Cleated Modular Plastic Belt |

| Grip Feature | Anti-slip Surface or Cleats |

| Max Product Height | 200 mm (customizable) |

| Applications | Assembly, Packaging, Vertical |

Z-Type and S-Type Modular Conveyors

Our S-type and Z-type modular conveyors are meant to counter applications demanding smooth movement across multiple elevations. They include interlock, bend-resistant belt modules that ensure proper product flow in the event of elevation changes. These conveyors find extensive application in snack processing, pharmaceutical, and packaging industry for better automation and minimum manual handling.

| Specification | Details |

|---|---|

| Structure Type | Z-type or S-type |

| Conveyor Height | Up to 4 meters (customizable) |

| Belt Design | Modular, Interlocking, Bend-Resistant |

| Cleanability | High (Wash-down Compatible) |

| Use Industries | Pharma, Food, Snacks, Packaging |

Heavy-Duty Modular Conveyor Systems

We also produce heavy-duty modular conveyor systems for extreme industrial use. They are strengthened by high-strength plastic belts and heavy-gauge steel frames to support heavy loads and heavy applications. Suitable for the automotive, logistics, and metal fabrication industries, these conveyors excel nicely in load capacity and operational reliability.

| Specification | Details |

|---|---|

| Belt Strength | Reinforced Plastic, High-Tensile |

| Frame Structure | Heavy-Gauge Mild/SS Steel |

| Load Support | Up to 300 kg/m² |

| Drive Mechanism | Heavy-Duty Gear Motor |

| Ideal Applications | Automotive, Logistics, Metal |

Key Features of Modular Conveyor Systems

A dominant Modular Conveyor Systems suppliers in Pune, our all types of new Modular Conveyor Systems are filled with new features inside such as:

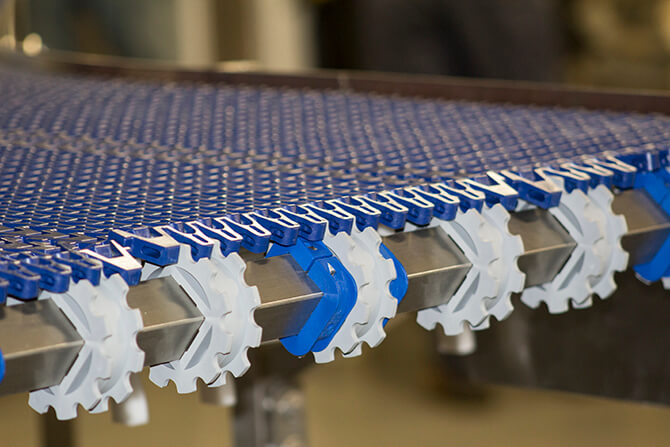

- Modular Belt for Plastic Conveyor: We integrate high-performance plastic substances like polypropylene, polyethylene, and acetal into our modular belts to give them strength, cleanliness, and wear. The belts are dependable in heavy loads and can be used for food-grade purposes as well as industrial purposes. The belts are non-corrosive, easy to clean, and designed to withstand extreme operating temperatures.

- Tool-less Maintenance Design: Our conveyors have the ease of maintenance in mind. Tool-free belt removal system allows fast cleaning, belt replacement, and visual inspection without skilled labor or special tools. It maximizes downtime reduction significantly and overall line productivity.

- Custom Width & Length Adjustability: We offer complete customization of our modular conveyors in terms of width, length, and support configurations. The systems are scalable or configurable to your evolving production needs without the need for redesign. Our conveyors conform to your tailored layout from the small warehouse to the large automated facility.

- Smart Conveyor Integration: We make our Industry 4.0 compatible modular conveyor systems such that they could be easily integrated into smart factory set-ups. Real-time monitoring, monitoring of energy consumption, reminder schedule for maintenance, and autoregulation features enable these conveyors to fit the needs of forward-looking production. Such integration helps in the minimization of breakdown and maximization of throughput.

Benefits of Modular Conveyors

These all types of new Modular Belt for Plastic Conveyor Manufacturers provides multiple types of benefits such as:

| Feature | Description |

|---|---|

| Easy to Sanitise and Hygienic | Naturally oil, water, and chemical build-up proof, ideal for food, pharma, and beverage applications. Smooth surface and open-hinge design provide high sanitation levels, reducing product contamination risk. |

| High Customization Potential | Highly adaptable systems with add-ons like side guards, cleats, sensors, and automation modules. Facilitate smooth changes without disassembling the entire system, ensuring scalability. |

| Longer Belt Life | Precision-moulded thermoplastic compounds provide resistance to deformation and elongation, extending working life and reducing belt changes, downtime, and maintenance. |

| Advanced Load Distribution | Interlocking modular construction evenly distributes weight, preventing sagging and enhancing product stability, especially under high speeds. Enables precise product placement in key applications. |

Applications of Modular Conveyor Systems

Being the best Modular Conveyor Systems exporters in Pune, our all types of Modular Conveyor Systems are included with new feature and highly used in multiple applications such as:

- Automotive Components Manufacturing: Our modular conveyors of heavy-duty types are used extensively for the transportation of small engine parts, assemblies, and metal components in car manufacturing facilities. Our conveyor systems are applied in harsh conditions where there is high mechanical stress and continuous operation. Our conveyor systems are built to transport safely with no damage to sensitive mechanical components.

- Pharmaceuticals & Healthcare: In pharma and healthcare sector, our conveyors are used for clean, contaminant-free transfer of syringes, vials, tablets, and medical packs. Our belts are anti-static and chemical-resistant and therefore perfectly suited for aseptic and cleanroom areas. They also pair perfectly with ideal packaging and inspection systems.

- Packaging Lines: Whether primary, secondary, or tertiary packaging, our conveyors ensure smooth and continuous motion down the line of production. They make automated packing lines continuous by feeding items to wrap, label, or seal with accuracy. Being as flexible as they are, they can be utilized in conjunction with robotic arms and vision systems.

- Food & Beverage Processing: We provide modular conveyors that meet the highest levels of safety and hygiene requirements in the food processing industry. The units are used to transport goods such as meat, bread, dairy, and confectionery without exposure to contaminants. Their stainless steel construction and smooth-to-clean belts provide them with a long life and safe operation.

Contek are Modular conveyor manufacturers, suppliers and exporters in Pune, offering the various quality of Modular Conveyor Supported by world-class service and adherence to global standards, we take pride in serving Pune as well as international markets. If you seek a trusty partner to power your material handling operation, your search ends at Contek. We would be glad to help you plan a more streamlined, mechanized, and look-to-the-future manufacturing facility.Contact us today

FAQ

A modular conveyor is a type of conveyor system built using interlocking plastic or metal modules, offering flexibility, easy maintenance, and custom configurations.

The modulus refers to the belt’s elasticity or stretch resistance, indicating how much it will elongate under tension during operation.

Load capacity is calculated based on belt strength, support spacing, motor power, and material weight, ensuring safe and efficient operation under load.

Regularly inspect for wear, tension the belt properly, and clean with mild detergents or pressure washers, avoiding harsh chemicals that damage the modules.