Part Runner Separator

Part Runner Separator Manufacturers, Suppliers and Exporters in Pune

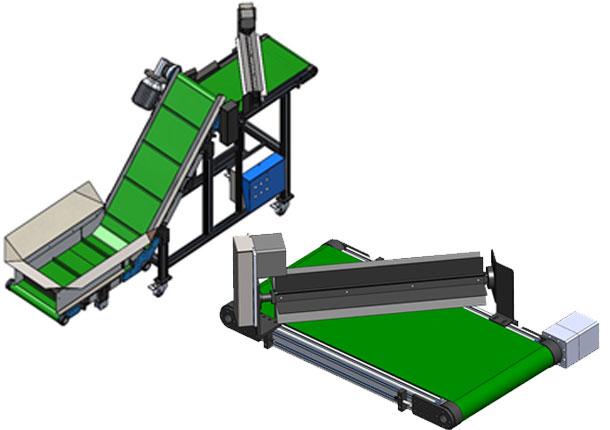

Contek is one of the prominent part runner separator manufacturers, suppliers and exporters in Pune, are offering best quality of part runner separator, Our separators are designed to deliver accurate performance and are built for heavy-duty application in plastic injection molding, assembly lines, and other production settings. For every system that we make, we attempt to help our clients reduce waste, increase production levels, and attain the highest degree of quality control

Types of Part Runner Separators

A well-known Part Runner Separator manufacturers in Pune, We are providing the best quality of Part Runner Separators such as:

1. Plastic Part Runner Separator

We specialize in producing high-speed Plastic Part Runner Separators utilized worldwide for plastic injection molding processes. They are capable of releasing molded products safely from runners at high speed without any harm to either product. They are also robot arm and conveyor-integrated-friendly, making them ideal for smart manufacturing lines where automation and precision are critical.

| Specification | Details |

|---|---|

| Compatibility | Injection Molding, Robotic Arms |

| Max Speed | Up to 60 cycles/min |

| Build Material | Aluminum + Industrial Plastic |

| Integration | Conveyor/Robot System Compatible |

| Control Type | Manual or Sensor- |

2. Automatic Part Runner Separator Systems

Our Automatic Part Runner Separator Systems are designed for companies that need maximum automation and minimal human intervention. They are equipped with industry-leading programmable logic controllers (PLCs) to control sorting speed, separation pattern, and real-time adjustments. We also employ smart sensors and AI-based algorithms to perform super-accurate separation, even small or complex parts, to help manufacturers reduce production errors and downtime.

| Specification | Details |

|---|---|

| Control System | PLC with AI Integration |

| Detection Type | Smart Sensors + Vision Systems |

| Sorting Speed | Up to 80 parts/min |

| Error Rate | < 1% |

| Interface Compatibility | SCADA, HMI, Industrial IoT |

3. Drum Type Part Runner Separators

We manufacture Drum Type Part Runner Separators ideally suitable for batch-type production plants. Our separators are equipped with tiltable drum inclines and screen removal to accommodate easily different part geometries. We have now improved this model with the addition of noise-absorbing panels and vibration control to achieve quieter operation and better stability at high-speed separation.

| Specification | Details |

|---|---|

| Drum Angle Adjustment | 0–30° Adjustable |

| Material Handling | Mixed Part Geometries |

| Noise Reduction | Integrated Acoustic Panels |

| Drum Material | SS304 with Powder-Coated Frame |

| Max Drum Speed | 50 RPM |

4. Compressor Oil Separator

We offer heavy-duty Compressor Oil Separators that drain oil from compressed air systems used in a wide range of industries efficiently. Our separators have high-efficiency coalescing filters that provide clean and dry air output and extend equipment attached to them, the maintenance cycle. Our newer models come with higher oil-holding capacity and are built to withstand harsh operating conditions without impacting performance.

| Specification | Details |

|---|---|

| Separation Efficiency | 99.99% Oil Removal |

| Operating Pressure | 16 bar (Max) |

| Filter Type | High-Efficiency Coalescing |

| Oil Holding Capacity | Up to 2.5 Liters |

| Housing Material | Epoxy-Coated Carbon |

5. Mild Steel Standard Air Oil Separator

Our Standard Mild Steel Air Oil Separators are of heavy-duty build and long life. They are used everywhere in automobile, HVAC, and industrial compressor units to facilitate effective draining of oil from air. The latest versions possess rust-proof coatings and support-backed constructs to survive more pressures, being thus welcoming to harsh working conditions.

| Specification | Details |

|---|---|

| Construction Material | Mild Steel with Anti-Rust Coating |

| Operating Range | -10°C to 90°C |

| Max Pressure | Up to 12 bar |

| Life Expectancy | 6000–8000 hours |

| Maintenance Type | Tool-Free Cartridge |

6. Standard Mild Steel Water Separator

We produce Standard Mild Steel Water Separators to drain water away from pneumatic systems and air lines to maintain the tools and machinery effectively. Standard Mild Steel Water Separators prevent water damage and corrosion to pneumatic systems. We also employ latest technology such as pressure indicators and automatic draining valves that provide real-time monitoring and ease in maintenance.

| Specification | Details |

|---|---|

| Working Pressure | Up to 10 bar |

| Separation Efficiency | 99% at Rated Flow |

| Body Material | Powder-Coated Mild Steel |

| Drain System | Automatic + Manual Override |

| Indicators | Pressure Gauge + Water Level |

Key Features of Part Runner Separators

A dominant Part Runner Separator suppliers in Pune, our all types of new Part Runner Separators are filled with new features inside such as:

- Our equipment comes with smart control panels featuring easy-to-use touchscreen displays and user-controllable settings for easy adjustment and control while in use.

- Each unit comes with a modular design philosophy, enabling quick upgrading, having easy cleaning procedures, and ease of maintenance.

- We offer high throughputs in capacity, enabling our separators to operate for extended periods in large-volume production lines without any degradation in performance.

- All our systems are energy-efficient and function on minimum energy but give equal output so that industries can attain goals of sustainability.

- We employ best-class materials such as food-grade stainless steel and powder-coated mild steel to deliver longer service performance even in unfavorable industrial conditions.

Advantages of Part Runner Separators

Our all types of new Automatic Part Runner Separator Systems manufacturer gives various types of benefits such as:

- We allow manufacturers to achieve improved working efficiency with reduced sorting time and quicker production cycle rates with precise part and runner separation.

- Our automation-based systems reduce manual labor use, allowing companies to redirect their labor to more complex tasks and reduce fatigue-driven errors.

- Low downtime of our products is realized through heavy-duty construction, reduced moving parts, and onboard diagnostics that alert operators in the event of failure.

- With advanced sorting technologies, including AI-based identification and sensor feedback, our separators achieve ongoing and accurate segregation with none at all of runners and parts cross-mixing.

- Our separators find versatile applications and can be used in automotive, electronics, medical devices, plastics, and other precision manufacturing industries.

Applications of Part Runner Separators

Being the best Part Runner Separators exporters in Pune, our all types of Part Runner Separators are included with new feature and highly used in multiple applications such as:

| Industry | Application | Benefit |

|---|---|---|

| Plastic Injection Moulding | Separation of parts and runners from multi-cavity moulds | Enhanced mould turnaround and reduced cycle time |

| Automotive Manufacturing | Sorting plastic and metal parts for advanced assemblies (engines, gearboxes, interiors) | Efficient sorting for complex assemblies |

| Medical Device Manufacturing | Separation of medical parts | Meets quality and hygiene standards, preventing contamination |

| Electronic Production | Separation of micro-components | High precision and care to prevent product failure |

| Pneumatic Systems and Compressors | Separation of oil and water from compressed air | Improved equipment efficiency, reliability, and lifespan |

Contek is one of the Best Part Runner Separator Manufacturers, Suppliers and Exporters in Pune, offered devices used in manufacturing (mainly injection molding) to separate finished parts from runners. We continue to improve to offer you systems that not only separate effectively but also optimize your overall productivity. With a strong support foundation, customized capability, and export-level performance, we cater to the domestic and international markets with pride. Choosing Contek is a commitment to precision, productivity, and long-term value for your production line. Get in touch with us today and experience the next generation of industrial separation technology. For more information, Contact us today !

FAQ

A part runner separator is placed at the end of a molding line to automatically separate molded parts from runners using rotating drums, conveyors, or screens.

Its purpose is to streamline post-molding operations by efficiently sorting usable parts from waste runners, reducing manual labor and cycle time.

It’s used in injection molding setups to separate finished plastic components from their attached runners, ensuring cleaner output and improved productivity.