Conveyor

Conveyor Manufacturers in Pune, Suppliers and Exporters in Pune

Contek India is one of the leading Manufacturers, Suppliers, and Exporters of Conveyor from Pune, Our experienced professionals designed automotive, precison and high-speed conveyors From low-profile belt conveyor to automation-capable intelligent platforms. our whole suite of solutions is yours to use to solve a broad spectrum of applications. With technology deployment on the leading edge and advanced industry knowledge, we make every conveyor system perform as reliably as you require it to. We aim to help organizations drive maximum levels of efficiency, reduce man hours, and stay competitive in a more technologically centered industrial age.

Conveyor Manufacturers in Pune

We Contek India are leading Conveyor Manufacturers in Pune, Suppliers and Exporters in Pune Our expert professionals offer a wide range of conveyors designed for efficient movement of goods across the industries worldwide. Our team specialized in delivering cost-effective & energy efficient conveyor solutions that enhance productivity and streamline material flow.

Types of Conveyor Systems

A well-known Conveyor manufacturers in Pune, We are providing the best quality of Conveyor such as:

Belt Conveyor

We offer high-speed belt conveyors that ensure flawless material handling for various industries. Our belts are constructed of best-in-class anti-slip material that minimizes the slippage of products and maintains operations secure. These systems are equipped with IoT-based load tracking, allowing the monitoring and performance to be tracked real-time. From parcels in an e-commerce warehouse to products in an FMCG factory, our belt conveyors deliver predictable output with minimal maintenance needs.

| Specification | Details |

|---|---|

| Belt Speed | Up to 2.5 m/s |

| Belt Material | Anti-slip PVC/Rubber |

| Load Capacity | Up to 80 kg/m² |

| Monitoring Feature | IoT Load Tracking |

| Application Areas | FMCG, Warehousing, E-commerce |

Modular Belt Conveyor

Our specially designed easy-maintenance modular belt conveyors are ideal for businesses where sanitation and maintenance are of utmost importance. The easy-clean, tool-free plastic modules enable the advantage of the capability of sanitation to be accomplished when needed and serve to complement this with minimal cost and effort. The conveyors are specifically ideal for food and pharmaceutical businesses where continuity of health requirement compliance and sanitation is even more vital than ever before. We also include hygiene monitoring instruments and smart sensors monitoring cleanliness factors and conveyor performance in real-time.

| Specification | Details |

|---|---|

| Belt Type | Interlocking Modular Plastic |

| Cleaning Mechanism | Tool-free, Water Washable |

| Hygiene Monitoring | Real-time Smart Sensors |

| Operating Temp Range | -10°C to +80°C |

| Ideal Industries | Food, Pharma, Healthcare |

Automation Conveyor

We build our automation conveyors 4.0-compliant, where synchrony, accuracy, and speed are the essence itself. They are all PLC-controlled, intelligent actuators equipped, and AI-driven back-end feedback loops adapting to changing production environments. The conveyors are robotics, vision systems, and real-time data communication to other smart machines. They are applied extensively in the automobile and electronics sector where micro-level accuracy and interrupt-free motion are the very essence of output efficiency.

| Specification | Details |

|---|---|

| Control System | PLC + AI Feedback Loop |

| Smart Integration | Robotics & Vision Compatible |

| Conveyor Accuracy | ±0.1 mm |

| Communication Protocol | OPC-UA / Modbus TCP/IP |

| Suitable Industries | Automotive, Electronics |

Part Cooling Mechanism Conveyor

Our part cooling conveyors are designed specifically for applications like die casting and injection molding where product temperature is of paramount importance to quality. They include integral cooling fans, cooled plates, and thermistors that give the optimum part temperatures during transit. With controlled cooling while in transit, we minimize energy expense and floor space consumed by individual cooling stations. They have a form and structural integrity in lengths before packaging or further processing.

| Specification | Details |

|---|---|

| Cooling Method | Fans + Cooling Plates |

| Temperature Sensors | Integrated Thermistors |

| Transit Temp Range | 35°C–70°C (Controlled) |

| Conveyor Length | Custom, Modular |

| Applications | Die Casting, Injection Molding |

Gravity Conveyor

Our gravity conveyors are an energy-saving solution for conveying light loads between packaging lines and warehouses. Equipped with precision-rolled rollers and heavy-duty frames, these systems offer tremendous power savings and man-reduction. The systems are best used where product stacking or hand transfer is needed. Their low cost of complexity and maintenance makes them the favorite of cost-conscious operations.

| Specification | Details |

|---|---|

| Roller Type | Precision Steel Rollers |

| Frame Material | Powder-coated Steel |

| Load Capacity | Up to 50 kg/m² |

| Slope Recommendation | 2° to 5° Gradient |

| Best Use Case | Warehouses, Sorting Lines |

Screw Conveyors

We produce screw conveyors to efficiently move bulk, powdered, and semi-solid materials in cement, agricultural, and chemical applications. They are produced using variable pitch screws that offer regulated flow rates and minimal clogging. They have dust-proof housings that bring in cleanliness and keep the environment free from contamination. They are ideal for moving material at inclined or vertical position where normal conveyors will be of no use.

| Specification | Details |

|---|---|

| Screw Pitch | Variable (Customized) |

| Material Compatibility | Bulk, Powdered, Semi-solids |

| Housing Type | Fully Enclosed, Dustproof |

| Incline Capability | Up to 60° |

| Typical Industries | Cement, Fertilizer, |

Vertical Conveyors

Our vertical conveyors are most appropriate for space-constrained environments where material transport must be in the upward or downwards direction. Our conveyors are equipped with smart position systems and servo-driven, allowing them to move back and forth precisely at varied levels. Our conveyors are widely used in modern warehouses, fulfillment centers, and multi-level production homes. With load tracking and safety, our vertical conveyors are safe and efficient vertical logistics.

| Specification | Details |

|---|---|

| Lifting Height | Up to 12 meters |

| Drive System | Servo Motor with Feedback |

| Load Capacity | Up to 100 kg per platform |

| Position Control | Smart Position Sensing |

| Applications | Fulfillment, Multi-Floor |

Motorized Conveyor System

We manufacture power-delivered conveyor systems consisting of power and precision for totally automated material transportation. With energy-saving motors and smart torque regulation, the systems respond dynamically to load conditions. They are optimally applied on high-speed packaging, sorting conveyor lines, and other time-limited applications. Their simple interfacing with smart manufacturing systems maximizes total process flow and reduces errors.

| Specification | Details |

|---|---|

| Motor Type | Energy-Efficient Induction/Servo |

| Torque Regulation | Smart Feedback System |

| Conveyor Speed | Variable (Controlled) |

| Integration Support | IoT, PLC, SCADA |

| Applications | Packaging, Sorting, Logistics |

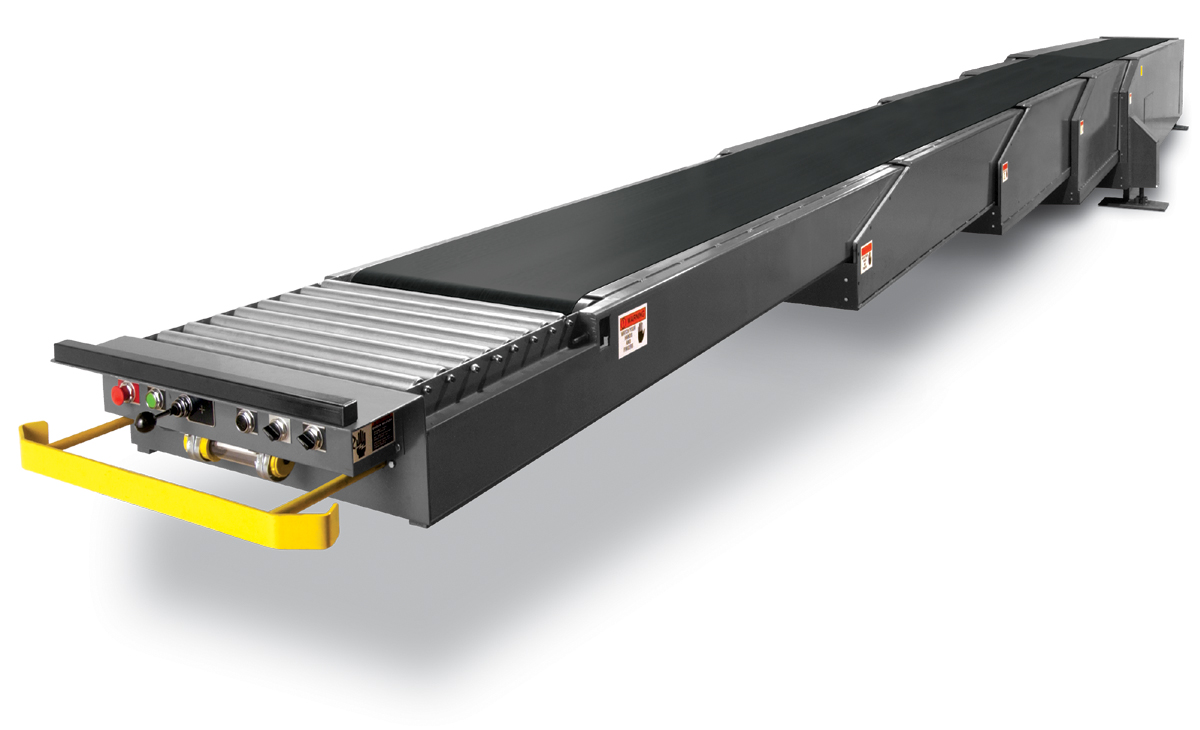

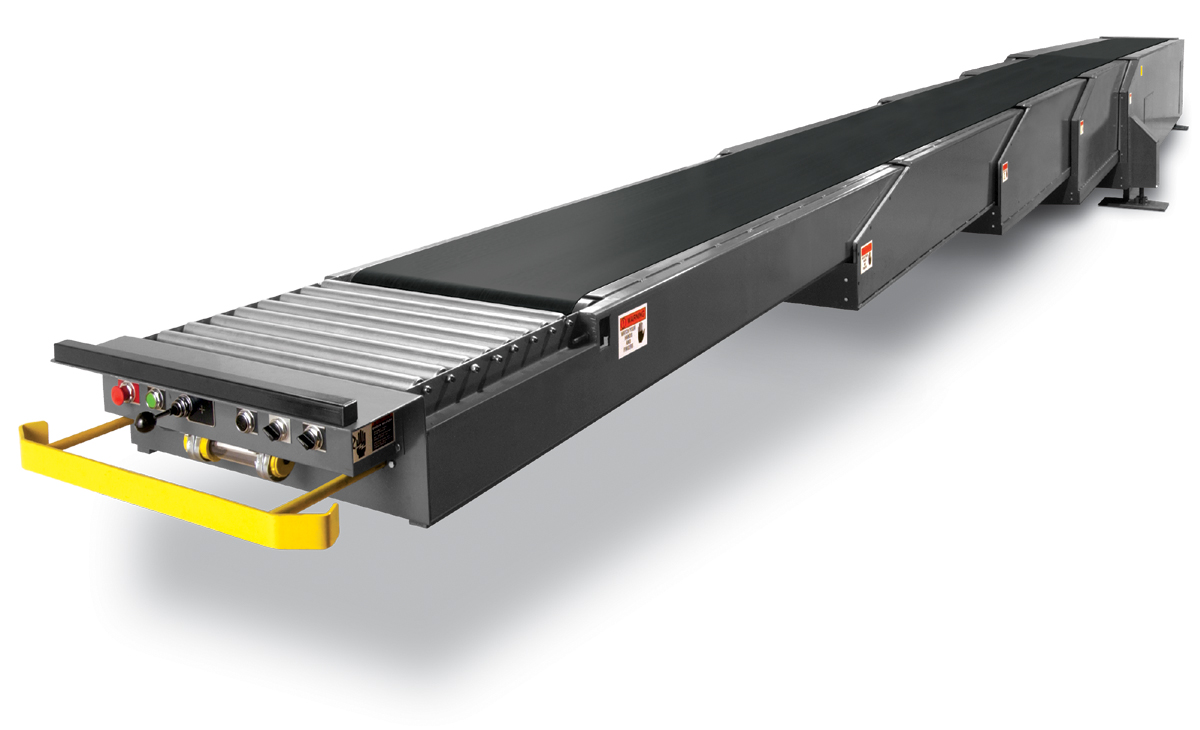

Loading Conveyor Systems

Our heavy-duty load conveyors are made for heavy-duty applications, particularly truck loading and unloading operations. With hydraulic height adjustability, telescoping extension, and heavy-duty lift, they facilitate loading and reduce the labor content of the workers. They function suitably where flexibility and speed are required by logistics companies, warehouses, and distribution centers. They are very reliable and experience low downtime when used under severe operating conditions.

| Specification | Details |

|---|---|

| Adjustment Type | Hydraulic Lift |

| Telescopic Extension | Up to 9 meters |

| Load Capacity | 50–100 kg/m |

| Frame Strength | Heavy-Duty Mild Steel |

| Use Cases | Truck Loading, Distribution |

Telescopic Conveyor Mild Steel

Our mild steel telescopic conveyors are rugged, extendable equipment for heavy-duty loading in industrial and logistic operations. They are built from strong mild steel, are equipped with safety sensors, easy control panels, and ergonomic designs. They reduce the use of manual power by extending into containers and trucks, thus enhancing the efficiency of loading as a whole. The systems best suit applications that require strength, dependability, and extended reach.

| Specification | Details |

|---|---|

| Material Build | Mild Steel (Reinforced) |

| Safety Sensors | Collision & Obstruction Detection |

| Control Panel | Manual + Digital Control |

| Extension Range | 6 to 12 meters |

| Ideal Use Cases | Industrial & Logistics Loading |

Features of Conveyor Systems

One of the leading Conveyor system suppliers in Pune, our all-types of Conveyor are included with new technological formulations such as:

- Automation-Ready Design: We engineer all of our conveyors with automation capacity so that it seamlessly fits into your smart factory network. From robot arms and vision systems to PLC control, our conveyors are built with the ease of coordination and communication in real-time. This makes compatibility reduce the amount of human intervention and improve the overall accuracy of flow. With automation-capable infrastructure, your factory is expandable and can be adapted to accommodate future technological upgrades.

- Modular Construction: We design our systems modularly to provide complete flexibility to your changing operation demands. Each module is detachable and re-attachable without halting existing workflow or initiating extensive redesigns. Rapid expansions, reconfigurations, or even complete system rebuilds based on seasonal or project-type loads are supported. Routine maintenance and component replacement are also facilitated by the modular setup, making it long-term compatible.

- Energy-Efficient Motors: We install energy-efficient IE3 and IE4 motors in our conveyor systems that minimize the energy required and the operational expenses by an enormous amount. Our heavy-duty and continuous operation stable motors ensure stable performance. Our carbon footprint-saving drive technologies don't save just carbon footprint but also allow you to achieve your sustainability goals. Not only do we conserve energy but also our cost-saving strategy gives you real cost savings.

- Low Maintenance: We focus on reducing your downtime by using components that are designed to last and are low maintenance. Rust-free frames, sealed ball bearings, and pre-lubricated parts remove frequent service checks. We incorporate smarter diagnostics that detect warning signs of wear and tear before they fail. Our systems therefore require less shutting down for servicing and last at optimal levels longer.

Applicationsof Conveyor Systems

Being the best sheet Conveyor Systems exporters in Pune, our all types of Conveyor Systems are included with new feature and highly used in multiple applications such as:

| Industry | Solution |

|---|---|

| Automotive | Full-process car manufacturing process-supporting conveyor systems ranging from chassis assembly to paint shop processing. |

| Pharmaceutical | Conveyors designed for single-pharma application where cleanroom compatibility, sanitary build, and precise control are necessary. |

| FMCG | Conveyor systems fundamental to high-speed consumer goods sectors like bottling, packaging, and palletizing operations. |

| E-Commerce | Expandable conveyor technology for e-commerce warehouses where loading, dispatching, and sorting need to be fast as well as accurate. |

We Contek India is one of the leading premier Conveyor Manufacturers, Suppliers and Exporters based in Pune. we attempt to optimize efficiency, demystify complexity, and amplify your vision of excellence in operations. Whether you’re automating production or upgrading material flow, our conveyors are designed to evolve with your business. We offer complete support from consultation to installation and after-sales service, ensuring a hassle-free experience. Partner with us today and discover how our smart conveyor systems can transform your workflow and boost productivity. Contact us today for more information!

FAQ

Common ones are belt conveyors, r oller conveyors, chain conveyors, screw conveyors, and pneumatic conveyors, each having applications in specific material handling operations.

Efficiency can be enhanced with maintenance, employmentof energy-efficient motors, reduction of friction, layoutoptimization, and incorporation of automation controls.

Conveyors handle materials with ease; belt conveyors are especially suitable for bulk or unit product shipping, while automation conveyors make production processes run smoothly in intelligent manufacturing plants.